4MW Biomass Boiler System

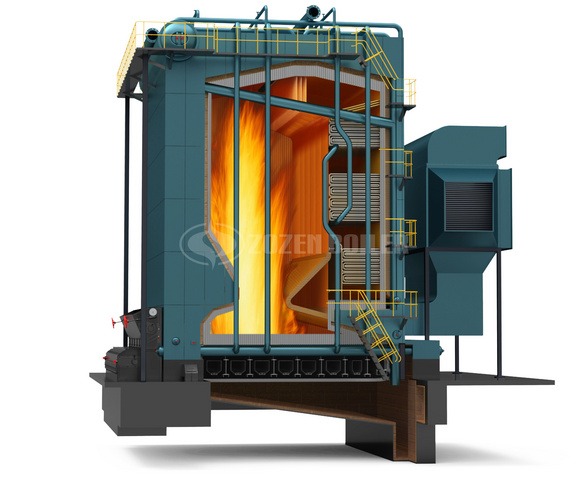

4MW biomass boiler system is a horizontal three-way water fire tube boiler. Two bundles of fire tubes are arranged in the barrel of the boiler, and light-tube water-cooled wall tubes are installed on both sides of the furnace chamber; the combustion adopts light chain grate to realize mechanical coal addition, and is equipped with blower and induced draft fan to realize mechanical ventilation. The fuel falls onto the grate from the coal hopper and burns after entering the furnace chamber with the grate. The flue gas passes through the upper combustion chamber of the rear arch and enters the tube bundle to the front flue box from the combustion chamber upward through the rear shed tube flue chamber, then folds into the second bundle to the rear flue box from the front flue box, and enters the flue, dust collector and chimney through the induced draft fan, and then discharges to the atmosphere.

4MW Biomass Boiler System

4MW biomass hot water boiler, it convection arrangement heating surface heat transfer efficiency, DZL biomass boiler system operation efficiency characteristics of smooth, overload operation capacity; and the use of water film dust collector, greatly reduce the dust emissions, in line with national emission standards. It control system adopts high brightness, full Chinese display, with famous brand PLC control system as the central control unit; it exchanges information with boiler users in human-machine dialogue mode to realize fully automatic and safe operation of boiler.

Technical Advantages of 4MW Biomass Boiler System

- Adopting high-efficiency insulation material, the boiler surface temperature is low and the heat dissipation loss is negligible.

- The boiler arch is made of pounded refractory concrete. The rear arch is low and long, so it burns well, and the two flue and side wall bricks are made of refractory sintered bricks. The front wall and back wall of the boiler are made of general-purpose refractory bricks.

- Built-in dust collector in the boiler, the emission is free of visible smoke and dust, which can be equipped with water film dust collector or cloth bag dust collector outside again to meet the requirements of the specified emission standard.

- All independent circuit design, for hot water boilers also use a reasonable lead shot cycle, the media flow rate in the heated surface circuit is higher than the national standard requirements.

- The water circulation is simple, the structure of the pressurized parts is reasonable, and it is completely safe to operate under the condition of ensuring water quality.

The DZL chain grate biomass boiler is a horizontal three-way water fire tube boiler, with threaded flue tubes in the barrel, water-cooled wall tubes on the left and right sides of the furnace chamber, new energy-saving furnace arches in the front and rear arches, light small-scale chain grate, which is conducive to the combustion of biomass fuel, equipped with blowers and induced draft fans for mechanical ventilation, and equipped with slag dispenser to achieve automatic slag discharge.

4MW Biomass Boiler System

Wuxi Zhongzheng Boiler Co., Ltd. has been specializing in the manufacture of gas steam, gas hot water and gas thermal oil boilers for 30 years, and the boiler models meet the standards of environmental protection requirements, low nitrogen emissions, low operation and maintenance costs, simple and convenient operation, and is a professional boiler manufacturer. We supply gas steam boiler, gas hot water boiler, gas heat transfer oil boiler, boiler manufacturer, guarantee the supply of excellent quality products!

Leave a Reply