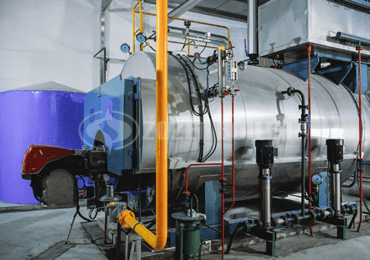

6 TPH Biomass Steam Boiler for Foam Material Factory in Vietnam

- Application Industry: Chemical Industry

- Project supporting boiler: SZL6-1.6-SCIII

- Project boiler medium: Steam

Case Introduction

A foam material factory in Vietnam aims to utilize the abundant local biomass resources to produce high-quality foam materials. The factory has strict requirements for boilers, not only demanding high efficiency and environmental performance but also needing the boilers to adapt to diverse biomass fuels.

In response to these requirements, ZOZEN provided two SZL series biomass steam boilers to the foam material factory, with each boiler having an evaporation capacity of 6 tons per hour, perfectly meeting the customer’s needs. The SZL series boilers are designed with international advanced technology and experience, and they possess the following significant advantages:

High efficiency: The design of the SZL series boilers ensures thorough combustion of fuel and efficient utilization of heat energy, greatly improving production efficiency.

Environmental performance: The emissions of pollutants during the combustion process of the boilers are extremely low, complying with strict environmental standards and helping to reduce environmental pollution.

Easy operation: The advanced automated control system makes the operation and maintenance of the boilers easier, reducing the workload and error rate of operators.

Adaptability to diverse fuels: The boilers can flexibly adapt to various biomass fuels, including biomass pellets, rice husks, and wood chips, fully utilizing local resources and reducing transportation costs.

The SZL series biomass steam boilers from ZOZEN not only meet the foam material factory’s strict requirements for high efficiency, environmental performance, and adaptability to diverse fuels but also help the customers optimize their production processes and effectively control costs through their excellent performance and reliable operation.

Customer Feedback

The boilers provided by ZOZEN Boiler not only meet our strict requirements for high efficiency and environmental performance but also have outstanding adaptability to diverse fuels, allowing flexible use of various biomass fuels such as biomass pellets, rice husks, and wood chips. This feature significantly reduces our fuel transportation costs and maximizes the utilization of local resources.

In practical operation, the SZL series boilers from ZOZEN Boiler have demonstrated excellent performance. The efficient combustion system and advanced automated control system not only enhance the thermal energy utilization efficiency but also simplify the operation process, reducing the workload and error rate of operators. We are also highly satisfied with the environmental performance of the boilers, as the emissions of pollutants are extremely low, fully complying with environmental standards and helping us achieve our green production goals.

Leave a Reply