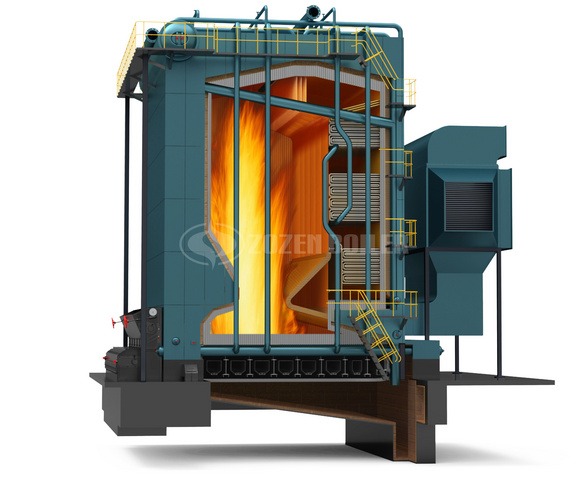

SZL Series Longitudinal Chain Grate Biomass Boiler

SZL series biomass boiler for a wide range of fuel, can use straw rice husk and other direct combustion fuel, molding biomass and biomass mixed fuel as fuel for combustion. Chain grate biomass boiler application range is wide, can supply process hot water steam, public heating, central heating and so on. The thermal efficiency of this series of boilers is high, the operating thermal efficiency is up to 87%.

Chain grate biomass boiler

Longitudinal chain grate biomass fired boilers is our company’s serialized mature products, the boiler adopts double cylinder longitudinal layout, combustion mode for chain grate. SZL series chain grate boiler has the characteristics of high automation level, safe and efficient operation, convenient installation and so on. The design optimization of this type of boiler solves the problem of easy coking of the boiler, improves the thermal efficiency significantly and saves the fuel cost.

The chain grate biomass boiler burns biomass molded solid fuel, and the water wall on both sides of the furnace adopts membrane type water wall structure. The water wall pipe of the front and back wall of the furnace extends down to the upper part of the grate to form a front and back arch, which not only increases the sealing performance of the boiler, but also increases the volume of the furnace and the heating surface, and at the same time strengthens the strength of the back arch. This series of biomass fired boilers fuel from coal scuttle land on fire grate, with, in the chamber of a stove or furnace combustion flue gas entering the convection bank area after the smoke baffle wall, flue gas flow to the s-shaped curve, using the inertia effect of dust in the flue gas separation after falling into the Settings below four gravity type hopper, falling with the grate operation with coal cinder in slag, the slag discharge machine furnace.

SZL series biomass boilers have high automation level, safe and stable operation, strong fuel applicability and high fume emission standard. After the furnace for burning chamber, convection tube bundle, tail economizer. The flue gas enters the tail flue through the furnace, embers chamber, convection tube bundle and economizer, and is discharged into the atmosphere through the dust collector, induced draft fan and chimney. The front wall is arranged with secondary air, controlled by the valve, which is put into use when burning biomass fuel to strengthen combustion, so that the fuel is fully burned out and the combustion efficiency is improved. Higher feed inlet is used to meet the demand of biomass fuel.

Chain grate biomass fired boilers

This series of chain grate boiler water circulation system is reasonable, large water capacity, steam space, steam quality is good. The air chamber can be adjusted manually according to the amount of air required in each combustion stage of the fuel. The transverse air pressure is consistent, and there will be no partial burning phenomenon. The lower part of the air chamber is equipped with the suction type cast iron ash discharging door, which is not easy to deform, easy to use and good sealing performance. Chain grate biomass boiler heat transfer efficiency is high, convection layout heating surface, boiler operation efficiency characteristics is stable and has a certain overload operation capacity. Welcome all users to consult and purchase, Zozen Boilers dedicated to the production of high quality boiler products, products exported to many countries and regions, has been praised by users.

Leave a Reply