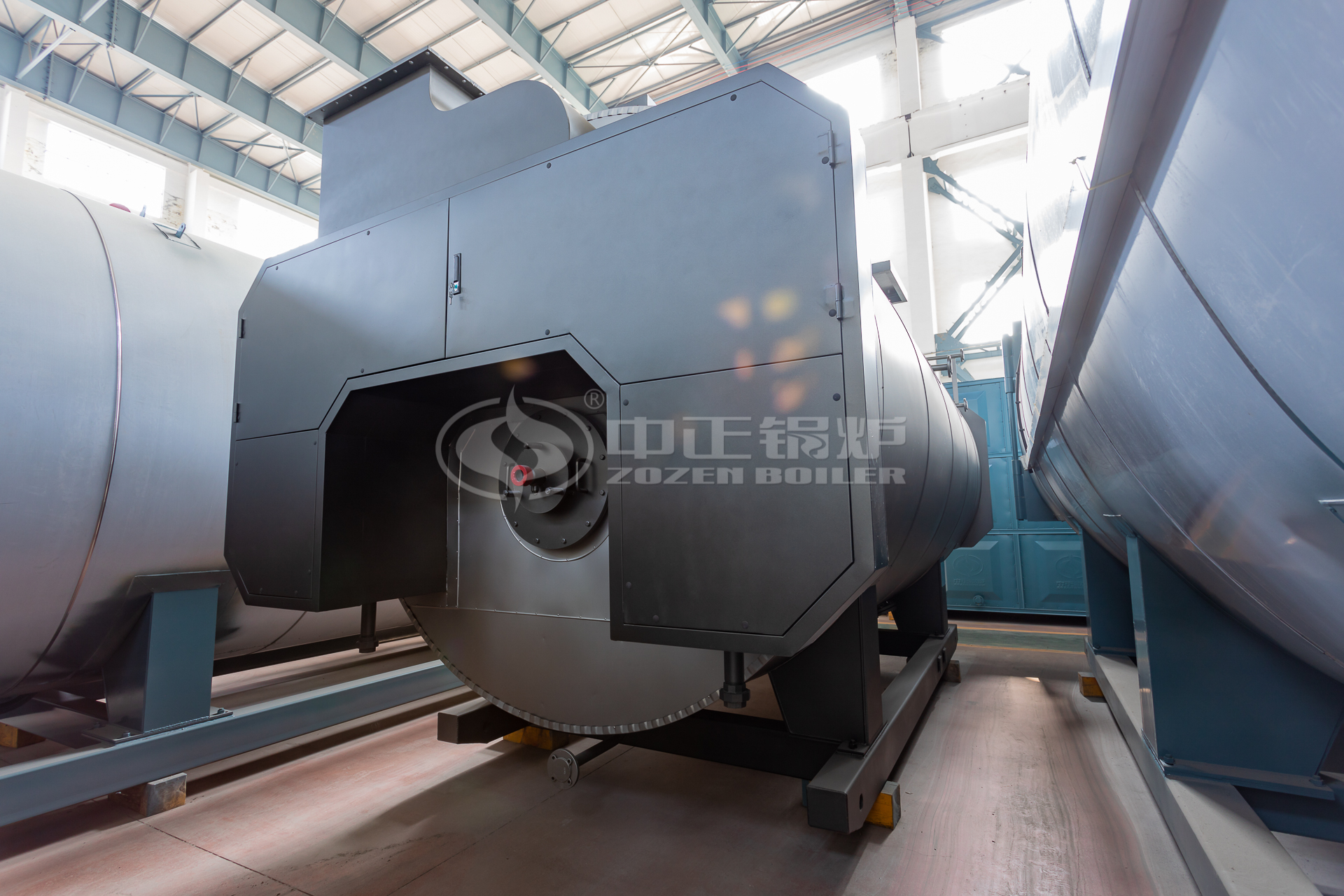

SZL Series Biomass Wood Boiler

Product thermal capacity: 6-35 t/h

Working pressure: 1-2.5 MPa

Available fuel: Biomass molding granules, wood chip, corn cob, saw dust, palm shells, rice husk, etc.

Available industries: Heating, chemical, food, tobacco, textile, print and dyeing, feed, medicine, building materials, wine, hospital

Biomass Wood Chip Boiler Introduction

The SZL series biomass wood boiler is a chain grate water tube boiler that utilizes wood chips, sawdust, and other wood waste as fuel. This biomass wood boiler offers an environmentally friendly alternative to traditional fossil fuels. The SZL series biomass wood boiler features a dual-drum design, enhancing heat transfer efficiency and providing a robust and stable structure. The chain grate ensures efficient combustion of the fuel and offers flexibility in handling various biomass wood fuel types.

Biomass Wood Chip Boiler Technical Features

Efficient Energy Utilization: The SZL series biomass wood boiler employs advanced combustion technology and design, enabling efficient utilization of biomass wood fuel by converting the energy in the fuel into heat energy, maximizing energy utilization efficiency. This helps reduce energy costs and decrease reliance on traditional energy sources.

Environmentally Friendly and Energy Saving: The SZL series biomass wood boiler complies with environmental standards and utilizes biomass fuel, significantly reducing emissions of carbon dioxide and other greenhouse gases. Compared to traditional coal-fired boilers, they have lower pollution emissions, making them more environmentally friendly. Additionally, biomass fuel is a renewable energy source, contributing to sustainable energy development.

Flexible and Diverse Fuel Adaptability: The SZL series biomass wood boiler exhibits excellent fuel adaptability, accommodating various biomass wood fuels such as wood chips, sawdust, and straw. This allows users to choose the appropriate fuel based on local resource availability and cost, enabling flexibility in response to market changes and energy supply conditions.

Reliable and Stable Operation: The SZL series biomass wood boiler is constructed with high-quality materials and refined manufacturing processes, ensuring exceptional quality and reliability. They undergo rigorous testing and quality control to maintain stable performance and efficient combustion during extended operation. Users can rely on these boilers without worrying about frequent breakdowns and maintenance issues, ensuring continuity and reliability in the production process.

SZL Series Biomass Wood Chip Boiler Specification

| Model | Rated thermal power (t/h) | Rated working pressure (MPa) | Rated steam temperature (℃) | Maximum transport dimension (m) |

| SZL6-1.25-SCⅢ | 6 | 1.25 | 194 | 6.20×2.80×3.65 |

| 7.20×2.60×2.80 | ||||

| SZL6-1.6-SCⅢ | 6 | 1.6 | 204 | 6.20×2.80×3.65 |

| 7.20×2.60×2.80 | ||||

| SZL6-2.5-SCⅢ | 6 | 2.5 | 225 | 6.20×2.80×3.65 |

| 7.20×2.60×2.80 | ||||

| SZL8-1.25-SCⅢ | 8 | 1.25 | 194 | 7.10×3.52×3.65 |

| 7.80×3.10×2.80 | ||||

| SZL8-1.6-SCⅢ | 8 | 1.6 | 204 | 7.10×3.52×3.65 |

| 7.80×3.10×2.80 | ||||

| SZL8-2.5-SCⅢ | 8 | 2.5 | 225 | 7.10×3.52×3.65 |

| 7.80×3.10×2.80 | ||||

| SZL10-1.25-SCⅢ | 10 | 1.25 | 194 | 7.90×3.52×3.65 |

| 8.40×3.10×2.80 | ||||

| SZL10-1.6-SCⅢ | 10 | 1.6 | 204 | 7.90×3.52×3.65 |

| 8.40×3.10×2.80 | ||||

| SZL10-2.5-SCⅢ | 10 | 2.5 | 225 | 7.90×3.52×3.65 |

| 8.40×3.10×2.80 | ||||

| SZL12-1.25-SCⅢ | 12 | 1.25 | 194 | 8.80×3.52×3.65 |

| 8.40×3.10×2.80 | ||||

| SZL12-1.6-SCⅢ | 12 | 1.6 | 204 | 8.80×3.52×3.65 |

| 8.40×3.10×2.80 | ||||

| SZL12-2.5-SCⅢ | 12 | 2.5 | 225 | 8.80×3.52×3.65 |

| 8.40×3.10×2.80 | ||||

| SZL15-1.25-SCⅢ | 15 | 1.25 | 194 | 9.60×3.20×3.65 |

| 8.30×3.30×3.00 | ||||

| SZL15-1.6-SCⅢ | 15 | 1.6 | 204 | 9.60×3.20×3.65 |

| 8.30×3.30×3.00 | ||||

| SZL15-2.5-SCⅢ | 15 | 2.5 | 225 | 9.60×3.20×3.65 |

| 8.30×3.30×3.00 | ||||

| SZL20-1.25-SCⅢ | 20 | 1.25 | 194 | 10.65×3.28×3.60 |

| 9.30×3.81×2.80 | ||||

| SZL20-1.6-SCⅢ | 20 | 1.6 | 204 | 10.65×3.28×3.60 |

| 9.30×3.81×2.80 | ||||

| SZL20-2.5-SCⅢ | 20 | 2.5 | 225 | 10.65×3.28×3.60 |

| 9.30×3.81×2.80 | ||||

| SZL25-1.25-SCⅢ | 25 | 1.25 | 194 | 11.65×3.80×3.60 |

| 9.30×3.81×3.00 | ||||

| SZL25-1.6-SCⅢ | 25 | 1.6 | 204 | 11.65×3.80×3.60 |

| 9.30×3.81×3.00 | ||||

| SZL25-2.5-SCⅢ | 25 | 2.5 | 225 | 11.65×3.80×3.60 |

| 9.30×3.81×3.00 | ||||

| SZL30-1.25-SCⅢ | 30 | 1.25 | 194 | 10.00×3.36×3.60 |

| SZL30-1.6-SCⅢ | 30 | 1.6 | 204 | 10.00×3.36×3.60 |

| SZL30-2.5-SCⅢ | 30 | 2.5 | 225 | 10.00×3.36×3.60 |

| SZL35-1.25-SCⅢ | 35 | 1.25 | 194 | 10.00×3.65×3.85 |

| SZL35-1.6-SCⅢ | 35 | 1.6 | 204 | 10.00×3.65×3.85 |

| SZL35-2.5-SCⅢ | 35 | 2.5 | 225 | 10.00×3.65×3.85 |

Leave a Reply