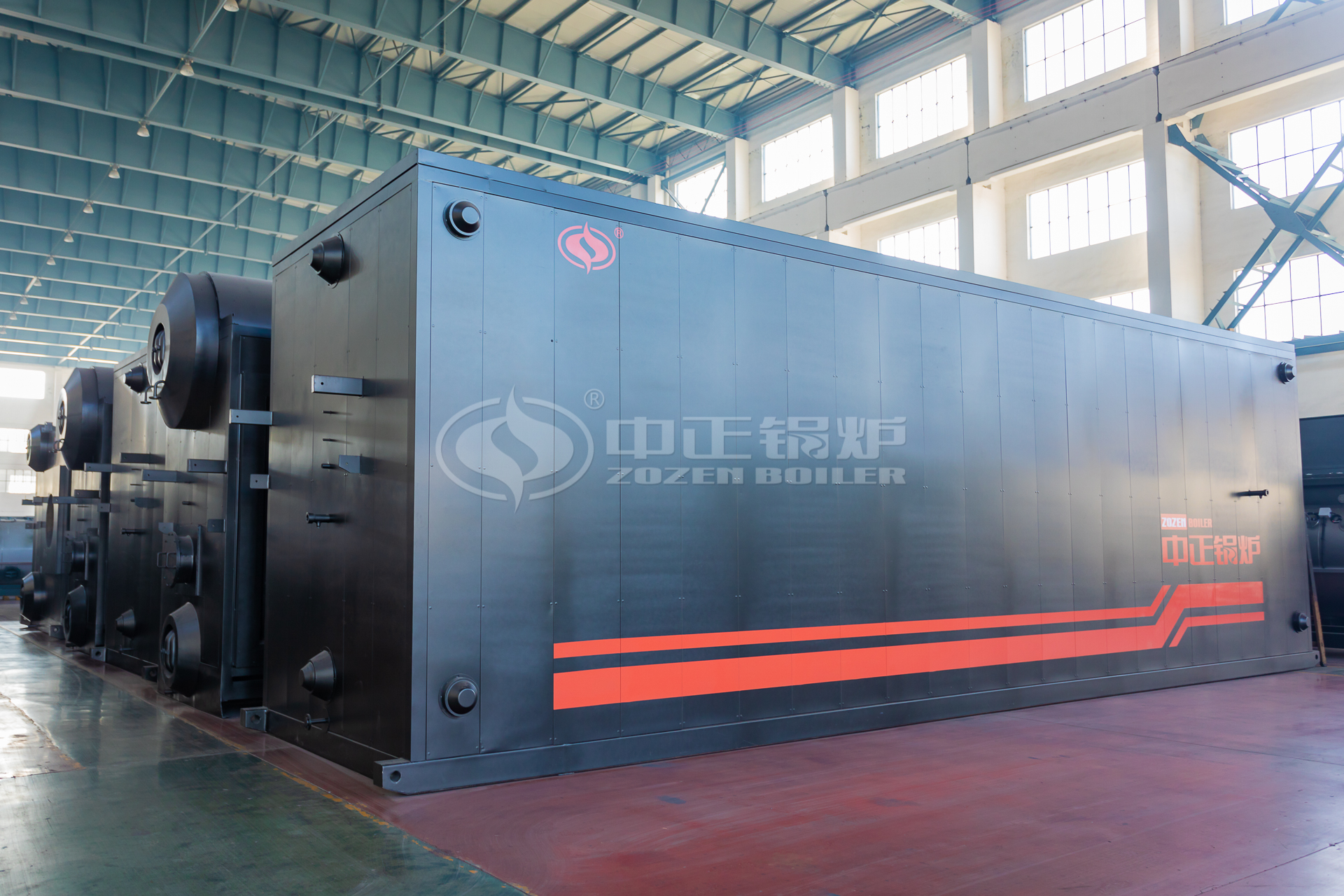

ZOZEN 4 Tph Biomass Steam Boiler for Food Processing Industry in Spain

- Application Industry: Food Processing Industry

- Project supporting boiler: DZL4-1.25-SS

- Project boiler medium: Steam

Case Introduction

Customer Feedback

We are highly satisfied with the steam boiler solutions provided by ZOZEN. Since the introduction of the 4-ton biomass steam boiler, our production efficiency has significantly improved, and the environmentally friendly emissions fully comply with European standards. The backup 1.5-ton diesel steam boiler has ensured production continuity during maintenance of the main boiler, greatly reducing the risk of downtime. The customized grate feeder and efficient auxiliary equipment tailored for us by ZOZEN’s professional team have made the system operation more stable and efficient. We believe that choosing ZOZEN Boiler is a significant step towards sustainable development and look forward to further collaboration with them in the future.

Leave a Reply