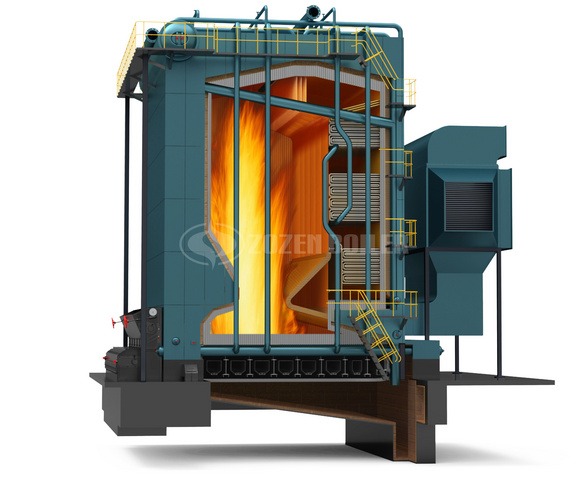

DHL Series Biomass Fired Steam Boiler

Product thermal capacity: 20-75 t/h

Working pressure:1.25-5.4 MPA

Available fuel: Biomass (straw, sawdust, bagasse etc.)

Available industries: Power generation, heating, chemical, food, rubber

DHL Series Biomass Fired Steam Boiler Advantages

Safe water circulation

- The boiler adopts a unique water circulation structure, the drum is free from heat and the heated water flows in one direction.

- In the event of a power outage, the water system does not vaporize and the water circulation is safe and reliable.

Anti-seismic Structure

Corner tube DHL series biomass fired steam boiler adopts non-framework structure, boiler proper weight is supported by membrane wall and down comer. And all membrane walls are all welded into one whole, with good anti-seismicity.

Complete sealed structure

- All around the boiler proper is made of welded membrane walls, and the steel structure is completely sealed to prevent the occurrence of air leakage.

- The upper part of the boiler can be divided according to the size of the railway transportation limit.

- The excess air coefficient after the heating surface of the boiler tail is only less than 1.2, which not only reduces the heat loss of the exhaust fumes, reduces the power consumption of the induced draft fan, but also greatly reduces the environmental pollution of the boiler house.

DHL Series Biomass Fired Steam Boiler Specification

| Model | Rated thermal power(t/h) | Rated working pressure(MPA) | Steam temperature(℃) | Thermal efficiency(%) |

| DHL35-1.25-M | 35 | 1.25 | 194 | 88 |

| DHL50-1.25-M | 50 | 1.25 | 194 | 88 |

| DHL75-1.25-M | 75 | 1.25 | 194 | 88 |

| ZZ-35/3.82-M | 35 | 3.8 | 450 | 88 |

| ZZ-50/3.82-M | 50 | 3.8 | 450 | 88 |

| ZZ-65/3.82-M | 65 | 3.82 | 450 | 88 |

| ZZ-75/3.82-M | 75 | 3.82 | 450 | 88 |

| ZZ-75/5.3-M | 75 | 5.3 | 485 | 88 |

Leave a Reply