Chain Grate Water Fire Tube Steam Boiler Supply

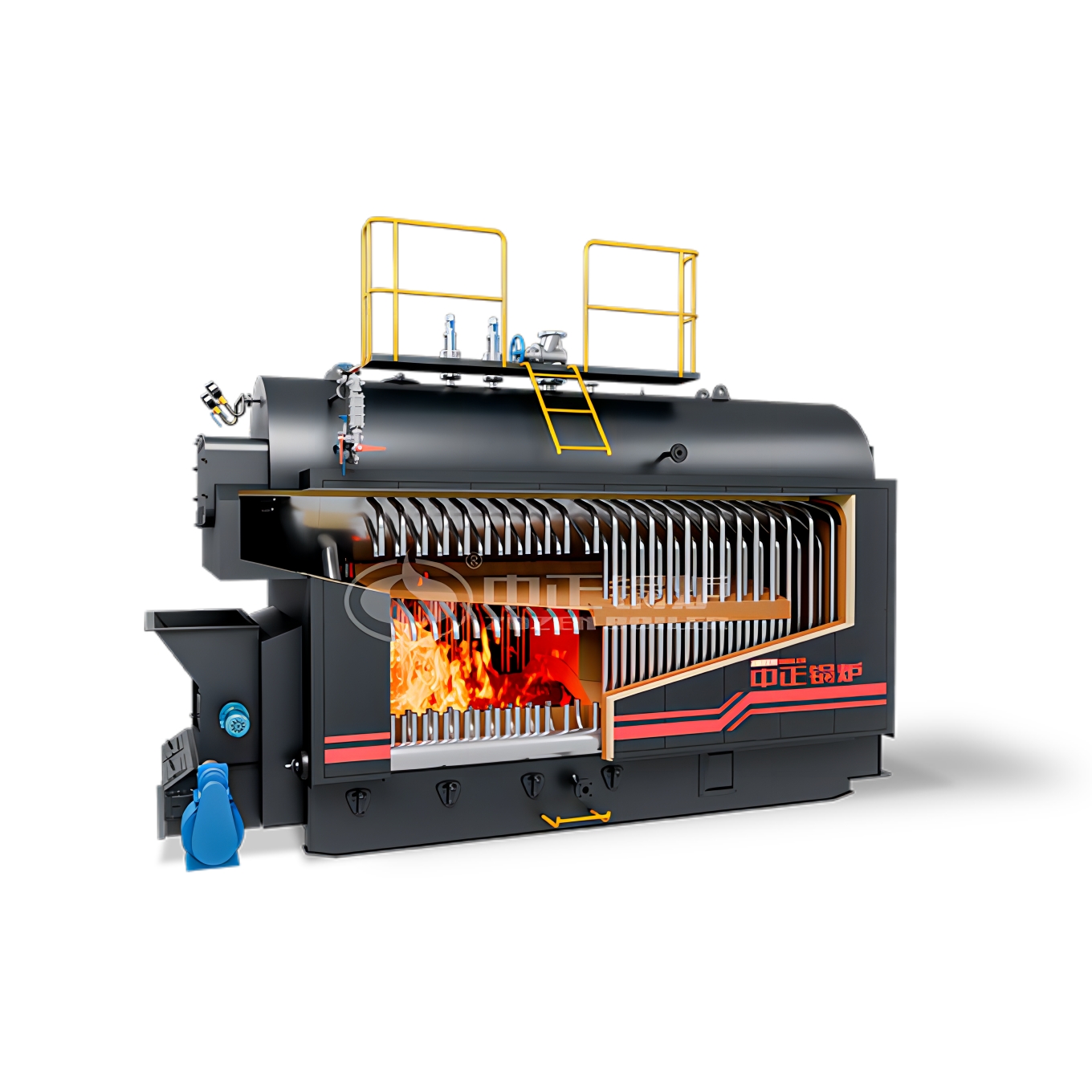

The chain grate boiler has the advantages of compact structure, small footprint and convenient installation. This series of boiler products adopt single drum longitudinal arrangement, natural circulation mode, water wall tube arranged on both sides of the drum into airfoil, effectively prevent the bottom of the drum due to scaling caused by bulge phenomenon. The design of the boiler tube plate is arch, welding stress to prevent the tube plate cracking. The water fire tube boiler use of threaded smoke pipe, strengthen the heat exchange, start up fast heating. The boiler has stable and reliable operation, sufficient hot water, stable heating and high thermal efficiency.

Water fire tube boiler

The chain grate steam boiler uses the threaded smoke pipe, the heat transfer coefficient of the threaded smoke pipe is twice as much as the light pipe. And under the guarantee of high heat transfer coefficient, optimize the design to achieve suitable flow resistance, no ash, small wear, high strength, anti-fatigue. Thread smoke tube soot cleaning ability, threaded pipe load half of flue gas flow rate is still can be in more than 8 m/s, more than in the velocity of threaded pipe produced by the ash removal ability (rotation of high speed air flow will be lower than half load set grey swept away), which sets ash phenomenon, make the type boiler in a constant output unchanged, the efficiency in the operation of all the year round.

Water-fire tube steam boiler is a kind of variable furnace arch structure low nitrogen oxide biomass boiler. Including front, middle and back three sections of the air chamber, chain or reciprocating grate, by the front arch, arch combination. Water fire tube boiler front air chamber and the back air chamber are arranged at the bottom to realize sectional air distribution. A grate is arranged above the air chamber in the front and back sections, the front section of the furnace tunnel is installed with an upward inclined front arch, and the back section of the furnace chamber is installed with an inclined back arch. The boiler combined with biomass fuel and combustion characteristics, so that the boiler to adapt to a wide range of biomass, burning degree is good, pollution discharge bottom effect.

This series of steam boiler adopts energy-saving, strong radiation furnace arch, strengthening combustion, strong adaptability, can ensure the stable and full combustion of fuel. The chain grate boiler produced by our factory adopts the inertia separation of the dust in the furnace and is equipped with an efficient multi-tube dust collector, so that the concentration of the dust discharged from the boiler can meet the requirements of the first class area. The boiler is equipped with reasonable water circulation loop and unique backwater ejection device, which improves the water speed of the riser pipe and avoids the explosion of the water wall pipe. The boiler adopts high standard, high quality auxiliary accessories and automatic control equipment to ensure the safety and stable operation of the boiler and reduce the labor intensity of the stokers.

Chain grate steam boiler

The water fire tube boiler operation is mechanized and the labor intensity of the stoker is reduced. The lower part of the steam boiler drum because of the arrangement of rising pipe row, eliminate the dead water area at the bottom of the drum, so that the sludge is not easy to deposit, the high temperature area of the drum can be good cooling, prevent the lower part of the drum bulge. The furnace layout of the boiler is reasonable and combustion. The boiler adopts a variety of environmental protection measures, such as bag dust removal, double tower desulfurization, so that the boiler soot discharge to meet the environmental standards. Zozen Boilers specializes in the production of various types of boiler products, and over the years, Zozen Boilers has reached a friendly cooperative relationship with many users, welcome to come to consult and purchase!

Leave a Reply