Coal Fired Steam Boiler In Malaysia

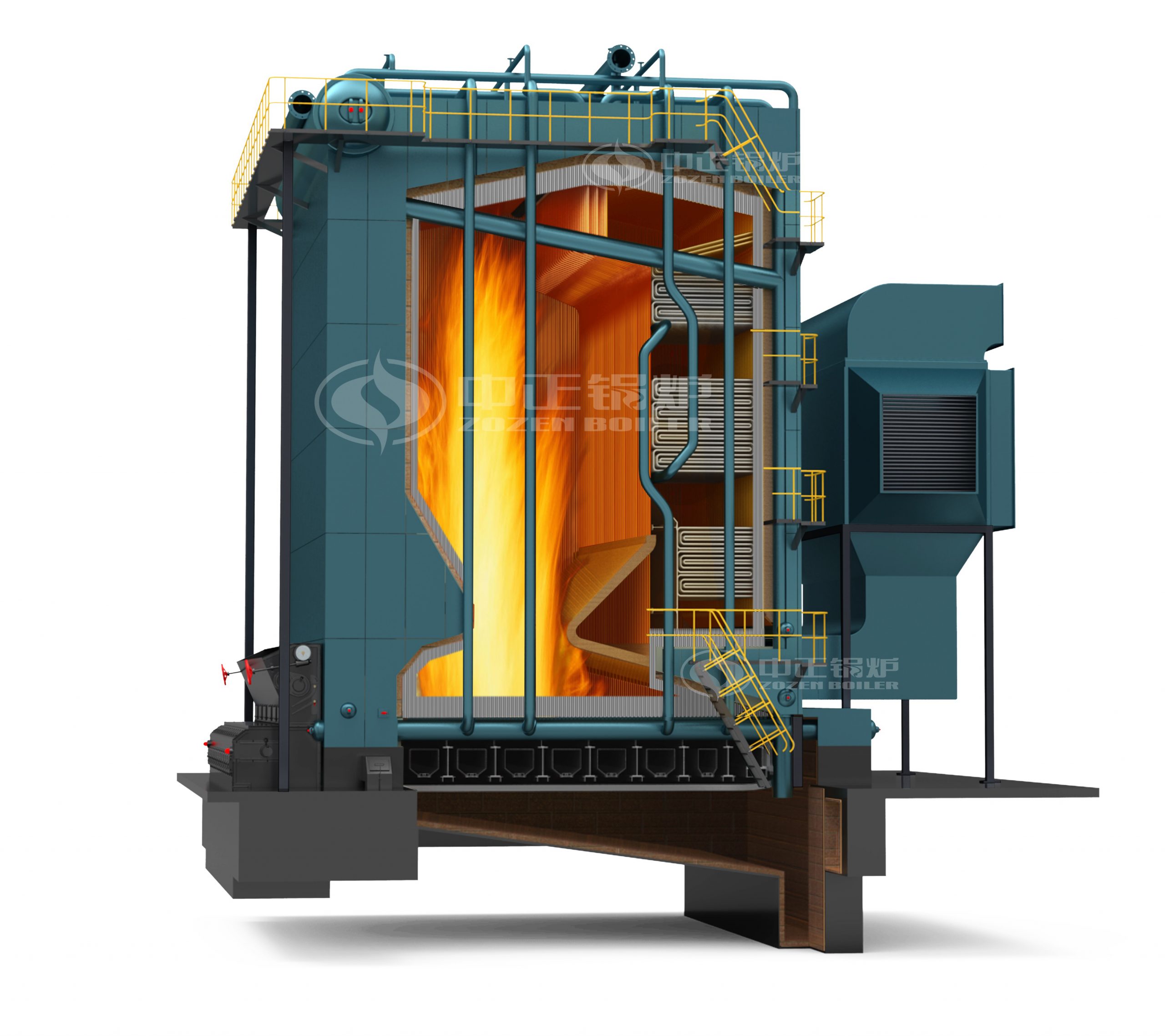

Generally speaking, coal fired steam boiler refer to the burning of coal as fuel. This series of steam boilers are equipped with light pipe water cooling walls on the left and right sides of the furnace. It adopts light chain grate to realize mechanical coal feeding, equipped with blower and induced draft fan for mechanical ventilation, and equipped with scraper type slag discharge machine to realize automatic slag discharge.

The front and rear arch of this series coal fired boiler adopts new energy – saving technology. After the fuel falls on the grate from the coal sill and enters the furnace for combustion, the flame, through the refraction of the rear arch, turns upward through the burning Chambers on both sides of the body and turns to the front smoke box, and then turns back to the tube bundle in the pot by the front smoke box, enters the economizer through the rear smoke box, and then is pumped by the induced draft fan to the air through the flue to the chimney.

Coal fired steam boiler

Coal Fired Steam Boiler Characteristics

- High thermal efficiency, safe and stable operation;

- The operation is mechanized, which reduces the labor intensity of the stoker;

- After delivery, install valve instrument, drum, induced draft fan, smoke air pipe, economizer, dust remover, slag extractor. Coal loader and water and electricity road can run, and has the characteristics of fast starting fire;

- Easy installation and movement can save a lot of capital investment.

This series of coal fired boilers are composed of boiler shell, head, furnace bile, furnace bile top, U-shaped ring, punch tube, etc. Its combustion chamber is arranged in the furnace bladder, and the furnace chamber is divided into two combustion Chambers by fireproof concrete furnace arch. The flue gas from the lower combustion enters the secondary combustion chamber through the throat on the arch of the fire-resistant concrete furnace and is mixed with the secondary air input from the upper furnace door. After radiation heat transfer through the heating surface of the furnace, the flue gas generated by the high temperature passes through the annular smoke box for convection heat transfer again, and is finally discharged into the atmosphere through the chimney.

Coal steam boilers for sale

The coal fired steam boiler adopts quick installation, simple and fast installation, compact and reasonable structure, convenient hoisting and transportation. Is widely used in hospitals, schools, textile mills, garment factories, garment, garment factories, dry cleaning shops, restaurants, hotels, shops, hotels, canteens of steamed buns, restaurants, food factory, beverage factory, bean products, meat products factory, cannery, brewery, pharmaceutical factory, packing plants, building materials factory etc. Zozen Boilers is professional boilers manufacturer, for many years, our products are sold all over the world, welcome to consult and purchase.

Leave a Reply