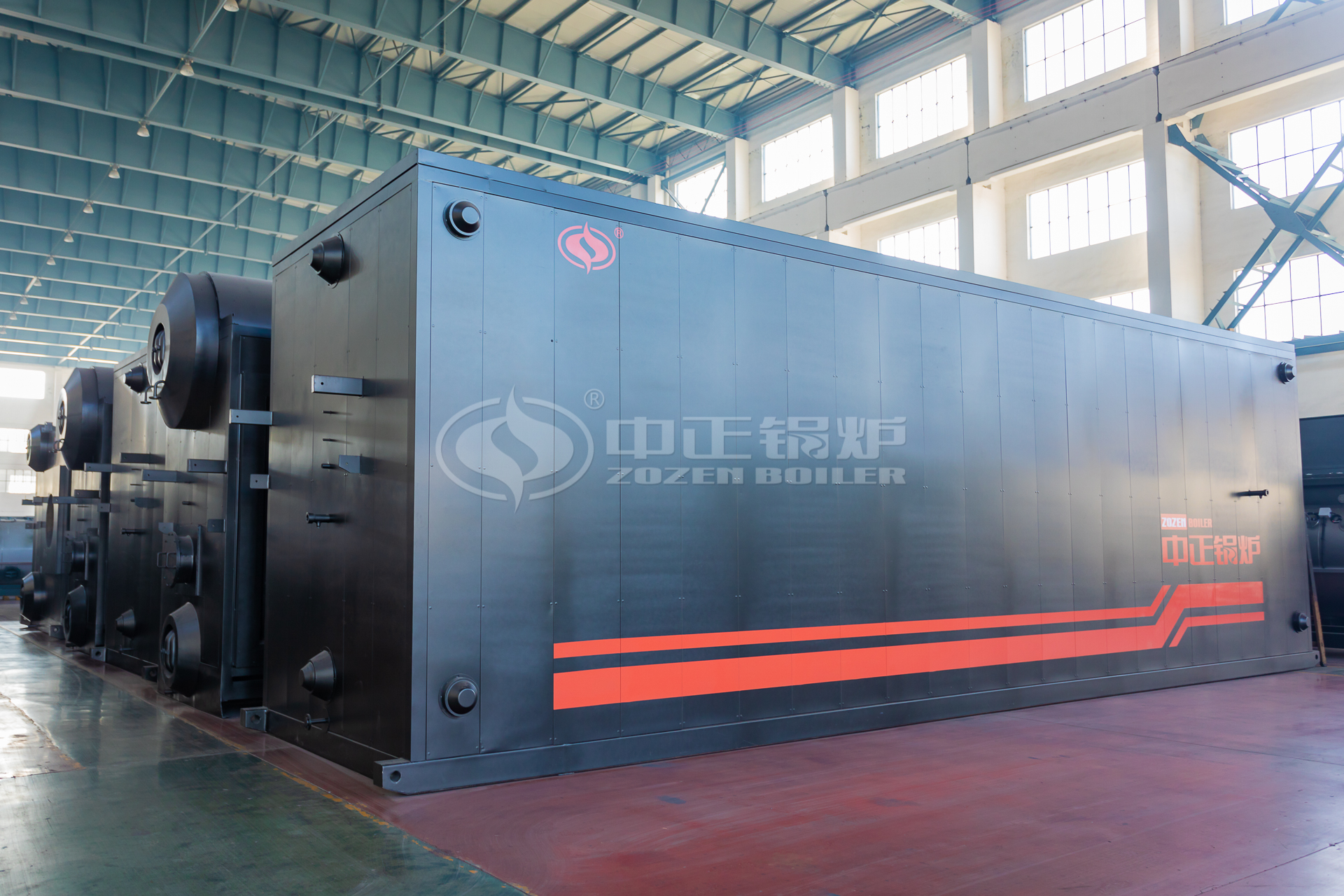

DZL Series Rice Husk Fired Steam Boiler

Product thermal capacity: 15-40 t/h

Working pressure: 1.25 MPa / 1.6 MPa / 2.5 MPa

Available fuel: Biomass molding granules, wood chip, corn cob, saw dust, palm shells, rice husk, etc.

Available industries: Heating, chemical, food, tobacco, textile, printing and dyeing, feed, pharmaceutical, building materials, brewing, rubber, hospitals.

DZL Series Rice Husk Fired Steam Boiler Introduction

The third generation of DZL series rice husk fired steam boiler is a type of water tube boiler composed of three drum boilers. Developed independently by ZOZEN Boiler, it possesses proprietary intellectual property rights for biomass boilers. The boiler adopts a modular structure, consisting of two main parts: the upper part is the main heating surface, and the lower part is the combustion equipment. The front part of the boiler body is arranged around the water cooling wall, the upper part is connected with the drum, the lower part is connected with the collecting box, and the combustion chamber is formed to absorb the radiant heat of the furnace. In the rear part, convective tube bundles are arranged between the upper and lower drums. After fuel combustion in the furnace, the high-temperature flue gas brushes across the heating surfaces of the convective tube bundles, then enters the economizer, and finally enters the dust collector before being discharged through the chimney.

DZL Series Rice Husk Fired Steam Boiler Advantages

- No ash accumulation: The ash blowing device is arranged on the convection heating surface of the boiler tail, and the ash blowing hole is left on the top of the furnace body. The ash blowing type is selected according to different fuels, and the ash can be cleaned without stopping the furnace

- Efficient Fuel Combustion: ZOZEN chain grate and independent air bin ensure thorough fuel combustion

- Thermal Efficiency>87.5%: Densely arranged water-cooled walls in the furnace offer large radiation area

- Simple Operation: Advanced controls automate fuel, ash removal, and slag discharge, streamlining operations

DZL Series Rice Husk Fired Steam Boiler Specification

| Model | Rated steam capacity (t/h) | Rated working pressure (MPa) | Rated steam temperature (℃) | Maximum transport dimension (m) |

| DZL15-1.25-SCⅢ | 15 | 1.25/1.6/2.5 | 194/204/225 | 10.10×3.15×3.60 |

| 8.50×3.42×3.00 | ||||

| DZL15-1.6-SCⅢ | 15 | 1.25/1.6/2.5 | 194/204/225 | 10.10×3.15×3.60 |

| 8.50×3.42×3.00 | ||||

| DZL15-2.5-SCⅢ | 15 | 1.25/1.6/2.5 | 194/204/225 | 10.10×3.15×3.60 |

| 8.50×3.42×3.00 | ||||

| DZL20-1.25-SCⅢ | 20 | 1.25/1.6/2.5 | 194/204/225 | 10.70×3.90×3.60 |

| 9.30×3.81×3.00 | ||||

| DZL20-1.6-SCⅢ | 20 | 1.25/1.6/2.5 | 194/204/225 | 10.70×3.90×3.60 |

| 9.30×3.81×3.00 | ||||

| DZL20-2.5-SCⅢ | 20 | 1.25/1.6/2.5 | 194/204/225 | 10.70×3.90×3.60 |

| 9.30×3.81×3.00 | ||||

| DZL25-1.25-SCⅢ | 25 | 1.25/1.6/2.5 | 194/204/225 | 10.70×3.90×3.60 |

| 9.30×3.81×3.00 | ||||

| DZL25-1.6-SCⅢ | 25 | 1.25/1.6/2.5 | 194/204/225 | 10.70×3.90×3.60 |

| 9.30×3.81×3.00 | ||||

| DZL25-2.5-SCⅢ | 25 | 1.25/1.6/2.5 | 194/204/225 | 10.70×3.90×3.60 |

| 9.30×3.81×3.00 | ||||

| DZL30-1.25-SCⅢ | 30 | 1.25/1.6/2.5 | 194/204/225 | 10.00×3.36×3.60 |

| DZL30-1.6-SCⅢ | 30 | 1.25/1.6/2.5 | 194/204/225 | 10.00×3.36×3.60 |

| DZL30-2.5-SCⅢ | 30 | 1.25/1.6/2.5 | 194/204/225 | 10.00×3.36×3.60 |

| DZL35-1.25-SCⅢ | 35 | 1.25/1.6/2.5 | 194/204/225 | 10.00×4.10×3.80 |

| DZL35-1.6-SCⅢ | 35 | 1.25/1.6/2.5 | 194/204/225 | 10.00×4.10×3.80 |

| DZL35-2.5-SCⅢ | 35 | 1.25/1.6/2.5 | 194/204/225 | 10.00×4.10×3.80 |

| DZL40-1.25-SCⅢ | 40 | 1.25/1.6/2.5 | 194/204/225 | 10.00×4.44×4.30 |

| DZL40-1.6-SCⅢ | 40 | 1.25/1.6/2.5 | 194/204/225 | 10.00×4.44×4.30 |

| DZL40-2.5-SCⅢ | 40 | 1.25/1.6/2.5 | 194/204/225 | 10.00×4.44×4.30 |

Leave a Reply