Enhancing Industrial Efficiency with Stoker Boiler

Introduction

Stoker boilers are a type of solid fuel combustion system widely used for industrial heating and power generation. These boilers utilize a stoker, a mechanical device responsible for feeding fuel into the combustion chamber. The stoker, through a controlled mechanism, ensures a continuous supply of fuel, allowing for efficient and reliable combustion. In this article, we will explore the characteristics of stoker boilers, discuss the factors to consider when selecting an appropriate stoker boiler, and highlight ZOZEN, a renowned manufacturer offering various stoker boiler options.

Characteristics of Stoker Boilers

One notable characteristic of stoker boilers is their ability to handle a wide range of solid fuels. This versatility allows for flexibility in fuel choices, making stoker boilers suitable for various applications. Stoker boilers are known for their robustness, reliability, and long service life. They are designed to handle solid fuels efficiently, ensuring high thermal efficiency and low emissions.

Selecting the Right Stoker Boiler

Choosing the appropriate stoker boiler requires careful consideration of several factors. The following aspects should be evaluated to ensure optimal performance and efficiency:

Fuel Type: Determine the type of solid fuel available and its characteristics, such as size, moisture content, and heating value. Different stoker boilers may be better suited for specific fuel types.

Thermal Capacity and Working Pressure: Assess the required thermal capacity and working pressure to meet the heating or power generation demands of the application.

Emission Control: Evaluate the environmental regulations and emission standards applicable to the location. Ensure the selected stoker boiler meets the necessary emission control requirements.

ZOZEN: A Leading Stoker Boiler Manufacturer

ZOZEN, a reputable boiler manufacturer, offers a wide range of stoker boilers to meet various industrial needs. Among their notable stoker boiler series are SZL, DZL, and DHL.

The SZL series is designed for coal or biomass combustion. These steam boilers have a thermal capacity ranging from 6 to 35 t/h and a working pressure of 1 to 2.5 MPa. The SZL series features a water-cooled wall tube arrangement, providing a large radiation surface area and high thermal efficiency.

There are two types in the DZL series. One is the DZL series non-clogging biomass-fired boiler with a thermal capacity of 15-40 t/h and a working pressure of 1.25-2.5 MPa. It is equipped with an ash blowing device at the rear convection surface and ash blowing holes on the top of the furnace. Different ash blowing modes can be selected according to different fuels, allowing ash cleaning without the need to shut down the boiler. The other type is the DZL series coal or biomass-fired water-fire tube boiler with a thermal capacity of 2-10 t/h and a working pressure of 1-2.5 MPa. It adopts threaded smoke tubes design, which increases the heat transfer coefficient by 1.8 times compared to ordinary smoke tubes.

The DHL series is designed for coal or biomass combustion and has a thermal capacity of 20 to 75 t/h, with a working pressure ranging from 1.25 to 5.4 MPa. These boilers can be customized with feed systems, slag discharge systems, and tail gas treatment systems to meet specific requirements.

ZOZEN’s product range also includes the YLW series of thermal oil boilers. The YLW series consists of horizontal coal or biomass-fired thermal oil boilers with a thermal capacity of 1400 to 29000 KW and a working pressure of 0.8 to 1.0 MPa. These boilers incorporate a customized flue gas waste heat recovery system to maximize thermal energy utilization.

ZOZEN and the Vietnamese Garment Factory Partnership

An exemplary collaboration between ZOZEN and a garment factory in Vietnam showcases the effectiveness of their stoker boilers. The garment factory has procured three highly efficient and energy-saving SZL series coal-fired steam boilers from ZOZEN. ZOZEN’s coal-fired boilers employ mature, clean coal technology that ensures ample production, high thermal efficiency, and broad fuel adaptability without compromising safety and reliability. To comply with local environmental requirements, ZOZEN has designed complementary dust removal, desulfurization, and denitrification equipment for the boiler’s tail, effectively reducing NOx emissions.

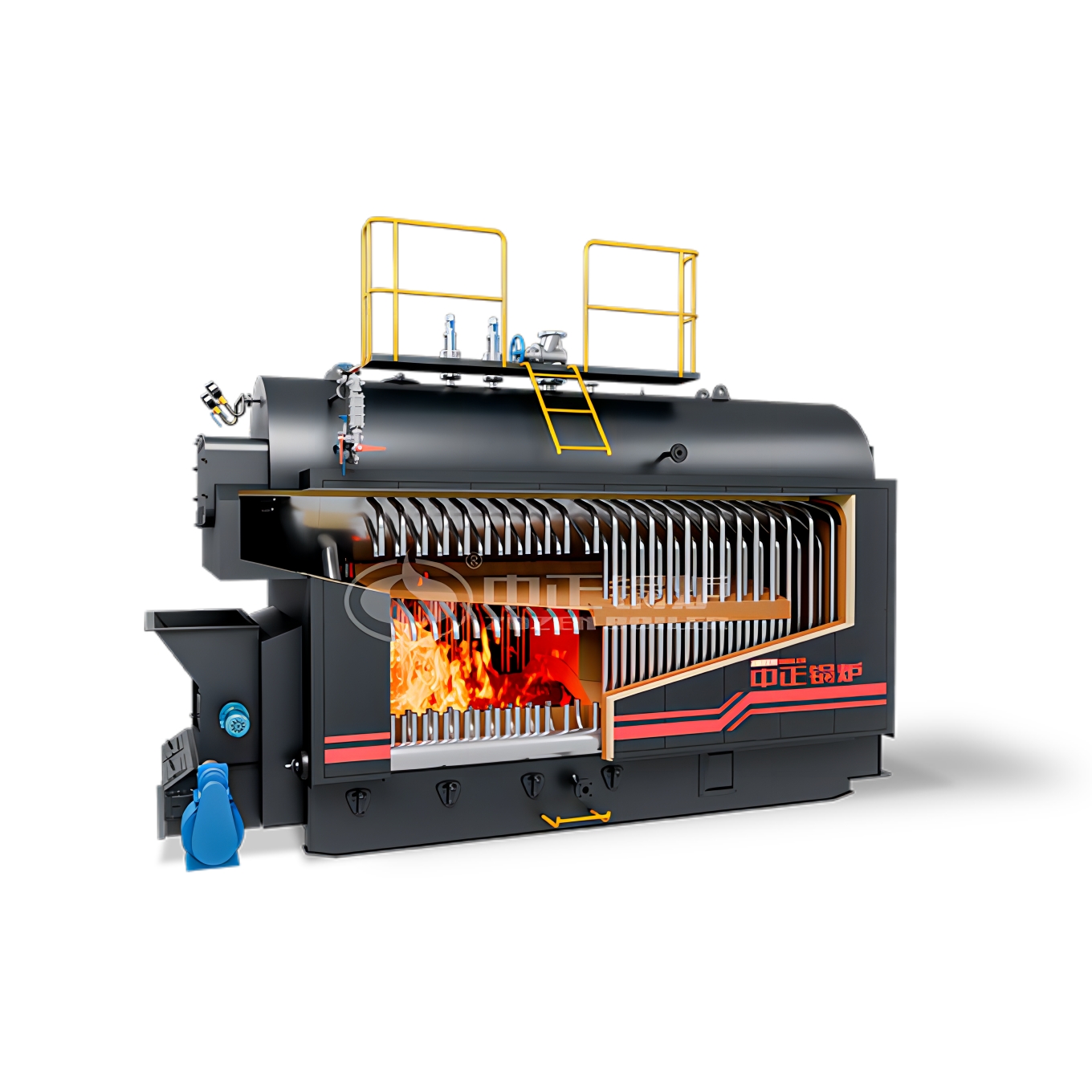

ZOZEN 10 Ton SZL Series Coal Fired Stoker Boiler

Conclusion

Stoker boiler offers a reliable and efficient solution for solid fuel combustion in industrial heating and power generation applications. When selecting a stoker boiler, factors such as fuel type, thermal capacity, working pressure, and emission control should be carefully considered. ZOZEN, a leading manufacturer, provides a range of stoker boilers, including the SZL, DZL, and DHL series, catering to different fuel types and application requirements. Their collaboration with a Vietnamese garment factory demonstrates the effectiveness and environmental advantages of ZOZEN’s stoker boilers. With their robustness, high thermal efficiency, and low emissions, stoker boilers from ZOZEN are a compelling choice for industries seeking reliable and sustainable solid fuel combustion solutions.

Leave a Reply