High Quality Coal Boilers in Indonesia

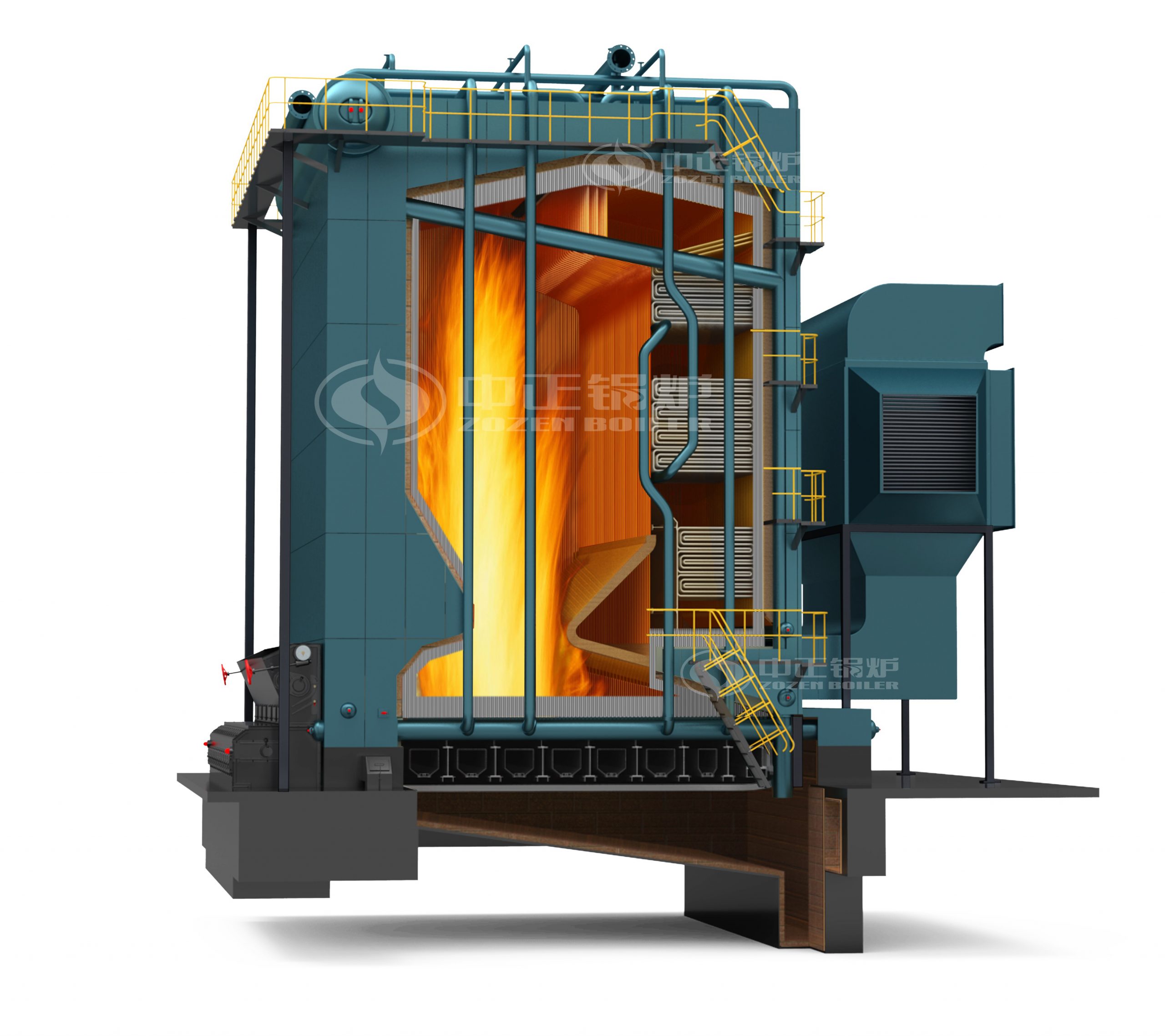

DHL series coal – fired boilers adopt membrane water – wall structure, the furnace, separator and return system cleverly arranged into one, compact structure. The coal boilers in Indonesia installed has a stable structure, and the water-cooled separator uses membrane wall as the separator’s skeleton, effectively preventing the separator’s efficiency from falling due to air leakage in the separator.

Coal boilers in Indonesia

The membrane wall of this series coal fired boiler absorbs heat to the lining, allowing the residual charcoal in the flue gas to continue burning in the separator without causing coking. The inner lining of coal – fired boiler separator has small thickness of wear – resistant material and small temperature difference between inner and outer surfaces. Its lining material internal stress is small, can prevent the crack damage, thermal inertia is small. Not only can the CFB boiler start and stop quickly, but also the separator runs safely and reliably.

The coal boilers in Indonesia was installed, boiler returns the system consists of two film water cooling walls, and part of the heat carried by the fly ash is absorbed by the water cooling walls. Its anti-wear design adopts a number of measures, the boiler as a whole adopts the design of low flow rate, the cross section area of the dilute phase of the furnace is large, the smoke speed is low. This series of boilers buried pipes are welded with anti-wear bars of special size and Angle to reduce the wear of buried pipes. At the same time, the buried area reduces the fluidization velocity. The separator is designed at the exit of the combustion chamber, and the larger particles in the flue gas are separated, effectively preventing the heating surface of the separator from getting worn. Wear resistant and high temperature materials are applied on the water-cooled membrane wall of the separator with high flue gas velocity to avoid wear of the membrane wall.

DHL series boiler coal has wide adaptability. Not only anthracite, bituminous, lignite and lean coal, but also gangue, gasification slag, chain slag and other inferior fuels. Waste slag can be comprehensively utilized, and the carbon content of slag is generally below 2%. The failure rate is very low and can run continuously for a long time. The product adopts low temperature combustion technology to effectively reduce harmful gas production. The emission of NO× can meet the environmental requirements in the case of any denitrification equipment. At the same time, the desulfurization can be carried out by adding lime to the furnace, which meets the requirements of environmental protection and energy conservation and emission reduction.

DHL series coal fired boiler for sale

This series of industrial boilers have high thermal efficiency, remarkable energy saving effect and environmental protection combustion technology. It has wide fuel adaptability, high combustion efficiency, large load adjustment range and fast load adjustment speed. DHL series coal fired boilers have high comprehensive benefit of ash slag, the carbon content of slag is 2%. Can be used as cement, brick, etc. The heating surface of buried pipe is arranged in the circulating fluidized bed, and the fuel system is simple.

Zozen Boilers is A company specializing in boiler manufacturers, the company holding a-class boiler manufacturing license, complete the qualification authentication, worth customer trust. Our company coal boilers in Indonesia, widely used in sugar refining and other food industries, with stable operation, reliable use, long life and high efficiency. Welcome to consult purchasing, we will serve you wholeheartedly.

Leave a Reply