Industrial SZL Series Water Tube Steam Boiler

SZL series water-cooled arch, membrane water-cooled wall assembly boiler is a patented product. Water tube steam boiler has high efficiency, strong overload capacity, wide adaptability of coal and advanced level. With high efficiency, strong overload capacity and wide adaptability of coal, the industrial water-tube boiler is honored as the best design scheme of contemporary similar products and has advanced level in the world. It is widely used in heating companies, textile factories, clothing factories, chemical plants, food factories, pharmaceutical factories, paper mills, wineries, water washing factories and other fields.

Water tube steam boiler

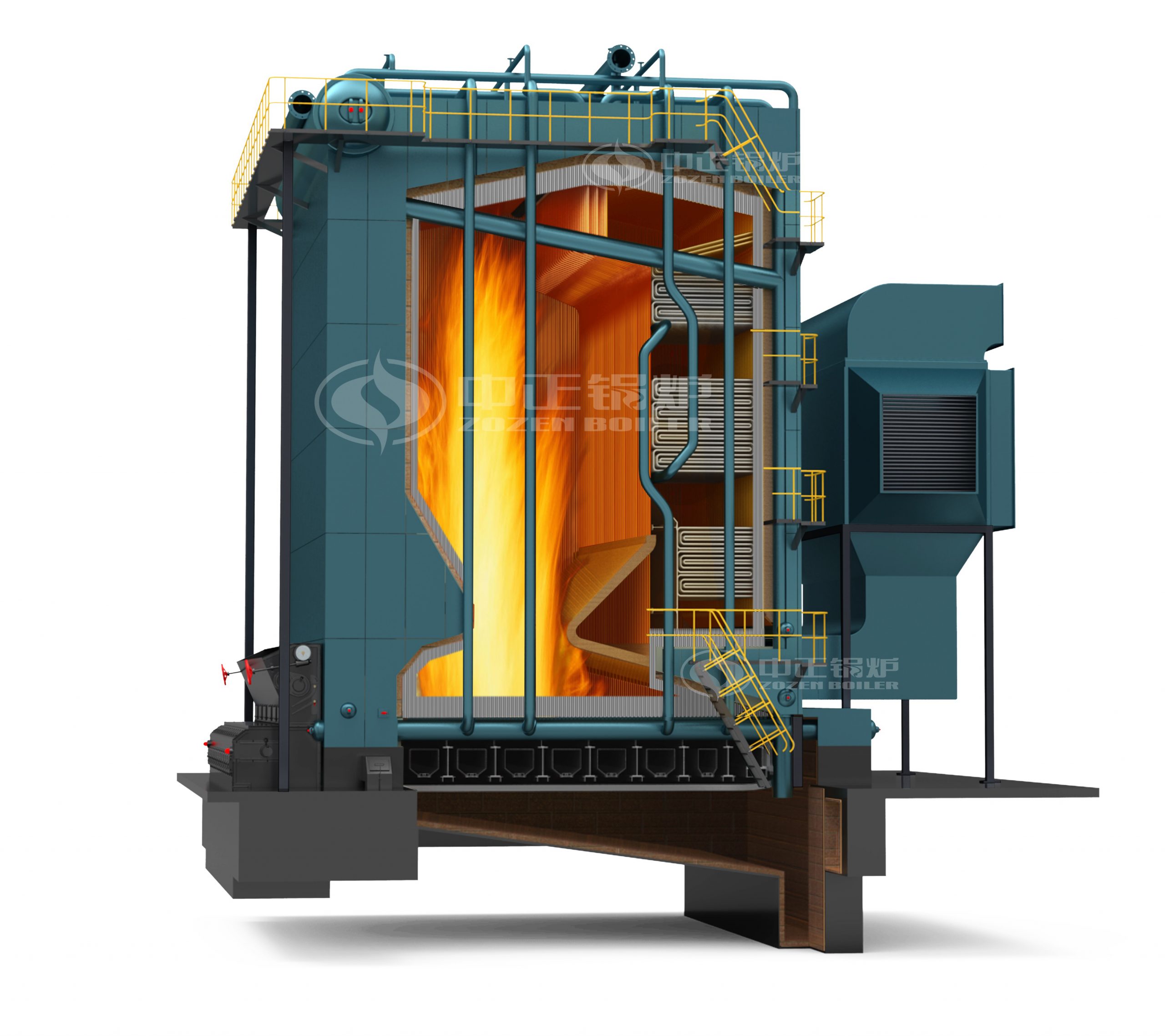

The SZL series steam boiler is mainly composed of upper and lower boiler tube, convection tube bundle, water wall tube, drop tube and header. The combustion equipment is chain-belt chain grate driven by stepless variable speed device. The boiler body is composed of longitudinally placed upper and lower boiler barrel and convection tube bundles. Water cooling wall is arranged around the combustion chamber, and the front and rear arches are made of water cooling wall as the skeleton casting refractory castable, and the furnace arch has a longer service life. On the left and right side of the body is the all-film water-cooling wall structure, which ensures the safe and efficient operation of the boiler with good sealing and small heat dissipation loss.

Water tube steam boiler has large heat transfer area, good conduction effect, low heat loss, good air tightness, no deformation of furnace wall and no ash leakage. The design of furnace wall and the application of energy saving device further reduce the heat loss of exhaust smoke and make the boiler more efficient. The upper part of the boiler is composed of main body, upper furnace wall and insulation layer. The lower bulk is composed of chain grate and coal scuttle. The radiant heating surface of the furnace is increased, and the overload capacity is stronger, and the service life of the furnace arch is prolonged.

In the design of industrial steam boiler, the front and rear axles of the grate are lengthened, the combustion is sufficient, the effective area of the grate is increased, and the overload capacity of the boiler is enhanced. After being closed with the supplementary heating surface at the site, only the lower furnace wall can be put into operation, with short installation period and less cost. Sectional air supply, good tightness, can control the combustion section of the air supply, to achieve the best regulation of the combustion effect.

The water outlet temperature of this series boiler is equipped with overtemperature protection device, which can automatically cut off the drum, induced draft fan and stop the rotation of the grate when the water temperature rises beyond the specified level or the circulating pump stops suddenly. The boiler is equipped with overpressure alarm and water level automatic adjustment device. The boiler has compact structure, small floor area and beautiful appearance. The boiler room needs only one layer layout and less investment in infrastructure project. The boiler is easy to operate, stable in operation, fast in temperature-rising and pressure-boosting, full in output, suitable for a wide range of coal.

SZL series water tube boiler

Water tube steam boiler is easy to operate, stable in operation, fast in heating and pressure boosting, full output, suitable for wide range of coal. Complete auxiliary equipment, drum, induced draft fan, water pump, dust collector can meet the boiler load requirements, wide range of speed regulation. The boiler has compact structure, small floor area, beautiful appearance, only one layer layout of boiler room and less investment in infrastructure project. Zozen Boilers products specializing in the production of high quality boiler, over the years dedicated to provide users with high-quality boiler solution, welcome everyone to come to advisory procurement.

Leave a Reply