Natural Gas Condensing Steam Boiler Has Reliable Performance

Natural gas steam boiler is to use effective flapping condenser and economizer to absorb the sensible heat in the high temperature flue gas excluded by the boiler and the latent heat released by the condensation of water steam to achieve the purpose of improving the thermal efficiency of the boiler. The main body of natural gas condensing boiler is wet-back three return, full corrugated furnace and threaded smoke pipe structure, which has good thermal scalability. The tube plate and cylinder of steam boiler are connected by an edging structure. The body of the main welding seam for the butt structure, all welding seam by automatic submerged arc welding.

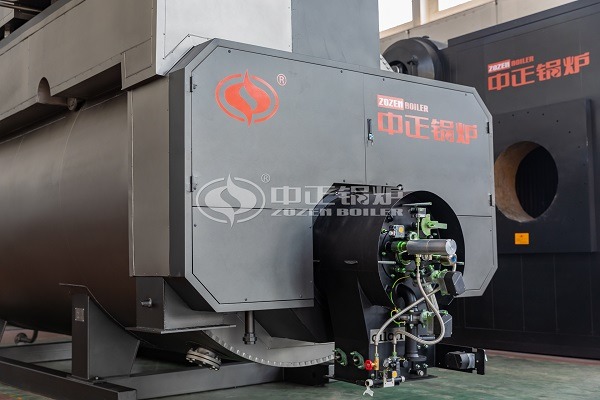

Natural gas condensing boiler

This type of gas fired boiler has sufficient heating area, large furnace structure, micro positive pressure combustion, low combustion heat load, and less harmful substances emissions. Boiler combustion chamber design is reasonable, effectively adapt to city gas, natural gas, light diesel, heavy oil and other fuels. Boiler flue gas blackness, soot blackness, concentration, noise and other technical indicators are better than the national class A regional standard. Condensing steam boiler radiation heating surface for the full corrugated furnace, convection heating surface using threaded smoke tube, heating surface, boiler thermal efficiency >105% above, higher than the relevant national regulations.

The radiation heating surface of natural gas boiler is full corrugated furnace bladder, and the convection heating surface uses threaded smoke pipe. The heating surface is large, and the thermal efficiency of the boiler is more than 105%, which is higher than the relevant national regulations. Natural gas condensing boiler using PLC full intelligent control system, high degree of automation. The company has independent design and development, and effectively has intellectual property rights of PLC automatic intelligent control system, using mechatronics control equipment and programmable logic controller (PLC) joint control mode. Programmable logic controller (PLC) is the “central processor” of the control system. The control system is operated by touch screen, which greatly improves the degree of boiler automation control and operation, and makes the operation more simple and intuitive.

The steam boiler condenser is made of steel spiral fin tube with excellent dew-point corrosion resistance of sulfuric acid and has long service life. The condenser of this series boiler products is installed in the upper part of the boiler, no occupation area, the condensate water on the heat transfer surface can be discharged naturally. Ontology safety accessories are complete to ensure safe and economic operation. With high quality and high performance burner, the combustion is stable and reliable. Boiler automation degree is high, saving labor. The boiler is small in size, light in weight, small in footprint and low in capital construction investment. Condensing steam boiler uses no noise, no pollution, high thermal efficiency, boiler body adopts high quality insulation material to do heat preservation, heat dissipation is small, energy saving and consumption reduction.

Natural gas steam boiler

Natural gas condensing boiler has high-tech automatic control, equipped with a number of protection devices. For example, water shortage protection, overpressure protection, flameout protection, abnormal pressure protection, flue overtemperature protection, etc. The boiler structure adopts high technology, it has the characteristics of small body protection, compact structure, convenient installation, simple operation and so on. Natural gas boiler automatic adjustment, the fuel pressure to atomization, micro positive pressure to make the fuel more fully, fuel loss and gas emissions, modern industrial steam is convenient to use, energy saving, environmental protection standard products.

Leave a Reply