SZL Series Biomass Steam Boilers Cost

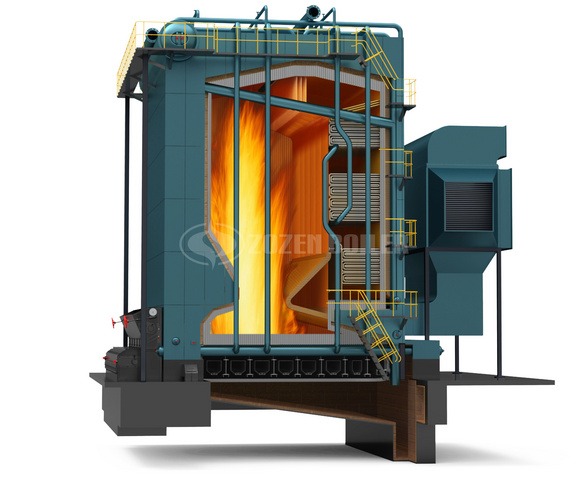

SZL series biomass boiler adopts new technologies such as heat transfer threaded pipe and arch pipe plate to improve the flow rate of flue gas, which makes the boiler reliable, energy-saving and high thermal efficiency. Biomass steam boilers cost reasonable, advanced structure, high thermal efficiency, fuel saving. The optimized furnace arch has the advantages of strong radiation, stable combustion, good effect and fast heating. Well-made water cooling wall, effective protection of furnace wall. Advanced performance and long service life. The main welding seam of the boiler adopts automatic welding, no repair record, to ensure the welding quality and improve the service life of the boiler. SZL series boiler tube plate adopts advanced pressing process to avoid the problem of tube plate cracking.

Biomass steam boilers cost

This series of biomass fired boiler combustion equipment adopts light chain grate, speed regulation adopts frequency conversion speed regulation, easy to adjust, stable operation, also can use reciprocating grate, better adapt to inferior fuel. Adopt the internal smoke and dust inertia separation, supplemented by multi – pipe dust remover or bag dust removal equipment. Automatic electric control system with complete monitoring instruments can realize automatic water replenishment, overpressure and overtemperature alarm, advanced remote control function, on-line monitoring of dosage, fault alarm and other functions.

SZL series boiler steam boiler combustion flue gas system, the fuel from coal scuttle land on fire grate, after entering the chamber of a stove or furnace burning, burning flame and high temperature flue gas, after the upper arch to combustion chamber into the state after return convection tube bundle, and then through the second and third convection bank process, by a third convection bundle exports of low temperature smoke gas, through the economizer, smoke by induced draft fan to the chimney into the atmosphere. Biomass steam boilers cost reasonable, compact structure, beautiful appearance, suitable for transport, easy to install.

Biomass steam boiler air distribution structure adopts the form of double-side air inlet dense air silo, in order to achieve the horizontal air distribution uniformity along the grate, and can realize the control of air distribution according to the combustion stage, in both sides of the boiler along the length direction equipped with seven damper, and seven ash handle, the stoker can reasonably adjust the damper opening according to the needs of combustion. The handle used for cleaning ash must be drawn twice in each shift during the operation of the boiler to make the ash fall on the backjourney grate surface, and then the backjourney grate will bring the leaking ash to the front and fall into the falling ash bucket.

The softened water after industrial biomass boiler treatment goes into the boiler barrel through the economizer, and a water distribution device is installed inside the upper boiler barrel. After the water entering into the upper boiler barrel is distributed, it goes into the descending tube, and then enters the side header, and absorbs heat through the water-cooled wall tube, and then returns to the upper boiler barrel. There is also a part into the lower pot tube, through the convection tube heat absorption back to the upper pot, the saturated steam from the top of the main steam pipe. In addition to the top of the pot is equipped with a valve, also equipped with a secondary steam valve.

SZL series biomass fired boiler sales

Biomass steam boilers cost of low operating, feed bin optimization design, prevention of tempering, secondary air distribution air design, can avoid coking. SZL series boilers are equipped with primary and secondary fans, with reasonable air distribution ratio, full combustion and avoiding coking. The service life of boiler is extended effectively. Zozen Boilers specializing in the production of boiler with high quality products, products are exported to more than 100 countries, involving chemical, pharmaceutical, paper making, printing and dyeing, hundred kinds of building materials industry.

Leave a Reply