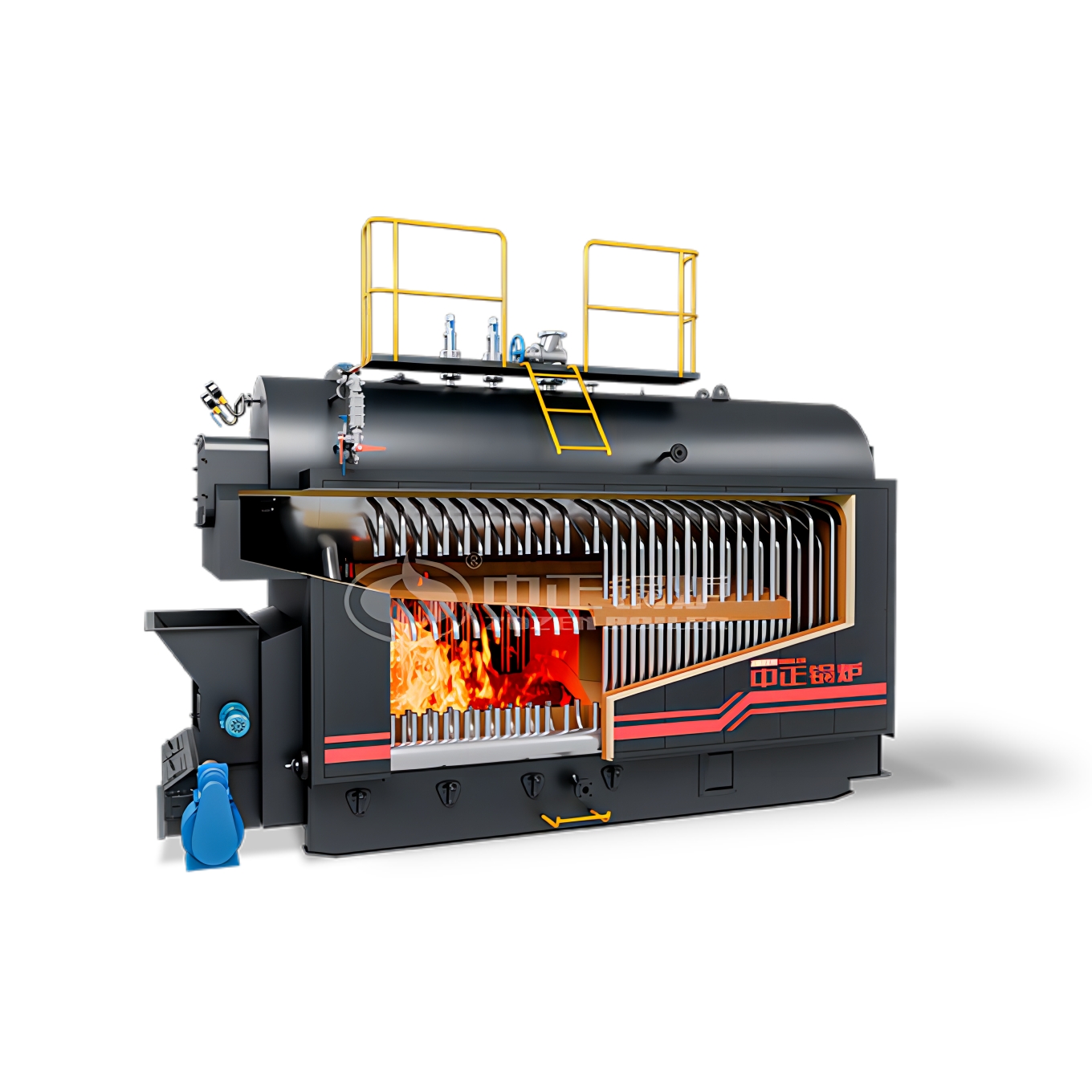

SZL Series Double Drum Biomass Steam Boiler Manufacturing

The thermal efficiency of biomass steam boilers of all specifications is >82%, which is higher than the national standard requirements. After the double drum steam boiler simplifies the water circulation circuit, the flow resistance of the water circulation is reduced. The flow rate in the riser pipe is increased. At the same time, this type of biomass boiler also improves the reliability of the water cycle and ensures the safe and stable operation of the boiler.

Double drum steam boiler

The biomass boiler is arranged with enough heating surface, so that the heat released by the fuel combustion can be fully absorbed by the heating surface and then transferred to the working medium, and the exhaust gas temperature is lower than 160℃. The front and rear arches of SZL series biomass boilers are reasonably arranged to increase the furnace temperature at the same time. It also strengthens the disturbance of flue gas in the high temperature area, reducing chemical incomplete combustion losses and fly ash losses. The use of large pieces of grate or scale-type grate, and to ensure that there is enough effective area of the grate, while improving the reliability of the grate operation, to ensure that the fuel is fully burned.

SZL series biomass steam boiler adopts double-side air inlet, separate air chamber, separate adjustment, stable combustion and reliable operation. This series of boiler products is equipped with a fume and dust inertia separation device at the furnace outlet, so that the original dust concentration of the boiler is lower than 1800mg/Nm³. The boiler is equipped with high-efficiency multi-tube dust collector and bag filter, and the flue gas emission of the boiler meets the requirements of the national first-class area. The double drum steam boiler has good sealing performance and small heat dissipation loss, ensuring the safe and efficient operation of the boiler.

The cases of SZL series boilers cover chemical, power generation, pharmaceutical, brewing, heating, papermaking, food, textile, rubber, tobacco, non-ferrous metals, building materials, feed and other industries. Taking the 10Ton biomass steam boiler as an example, the boiler can run stably under 70%-100% working conditions. Under the condition of 100% rated load, the operating parameters of the boiler are as follows: the feed water temperature is 20°C, the rated pressure of the boiler is 1.25MPa, 10 tons of steam with a temperature of 193°C are generated, the calculated thermal efficiency is 81.22%, and the exhaust gas temperature is 155°C.

SZL series biomass steam boiler

The water-cooled wall tubes of the double drum steam boiler are closely arranged, which effectively reduces the temperature of the furnace walls on both sides. Therefore, light-weight furnace walls can be used for the rear furnace walls of the water-cooled walls on both sides, which can effectively reduce the transportation weight, and has the characteristics of quick start-up and quick heating. This series of steam boilers are divided into two parts, which are easy to install and move. After the assembled boiler leaves the factory, it is only necessary to combine the two parts, build the upper and lower furnace walls, and install auxiliary systems such as slag machines and fans. It can be operated by connecting the water and electricity, etc., the installation is convenient, and the cycle is short.

Leave a Reply