The Crucial Role of Power Plant Steam Boiler in Electricity Generation

Introduction

Power plant steam boiler plays a vital role in the process of electricity generation, serving as the heart of power plants worldwide. These industrial boilers are responsible for converting water into steam, which drives turbines to generate electricity. The efficiency and reliability of these boilers are of utmost importance to ensure uninterrupted power supply and optimal performance.

Part 1: The Core Importance of High Efficiency and Reliability

In the realm of power generation, efficiency and reliability are paramount. Power plant steam boiler must operate at high efficiency to maximize the conversion of fuel energy into steam and subsequently into electricity. This not only reduces fuel consumption but also minimizes environmental impact by lowering emissions. Reliable operation is equally critical as any downtime can lead to significant economic losses and disrupt the power supply to countless consumers.

Part 2: Introduction to ZOZEN and its Expertise in Industrial Boilers

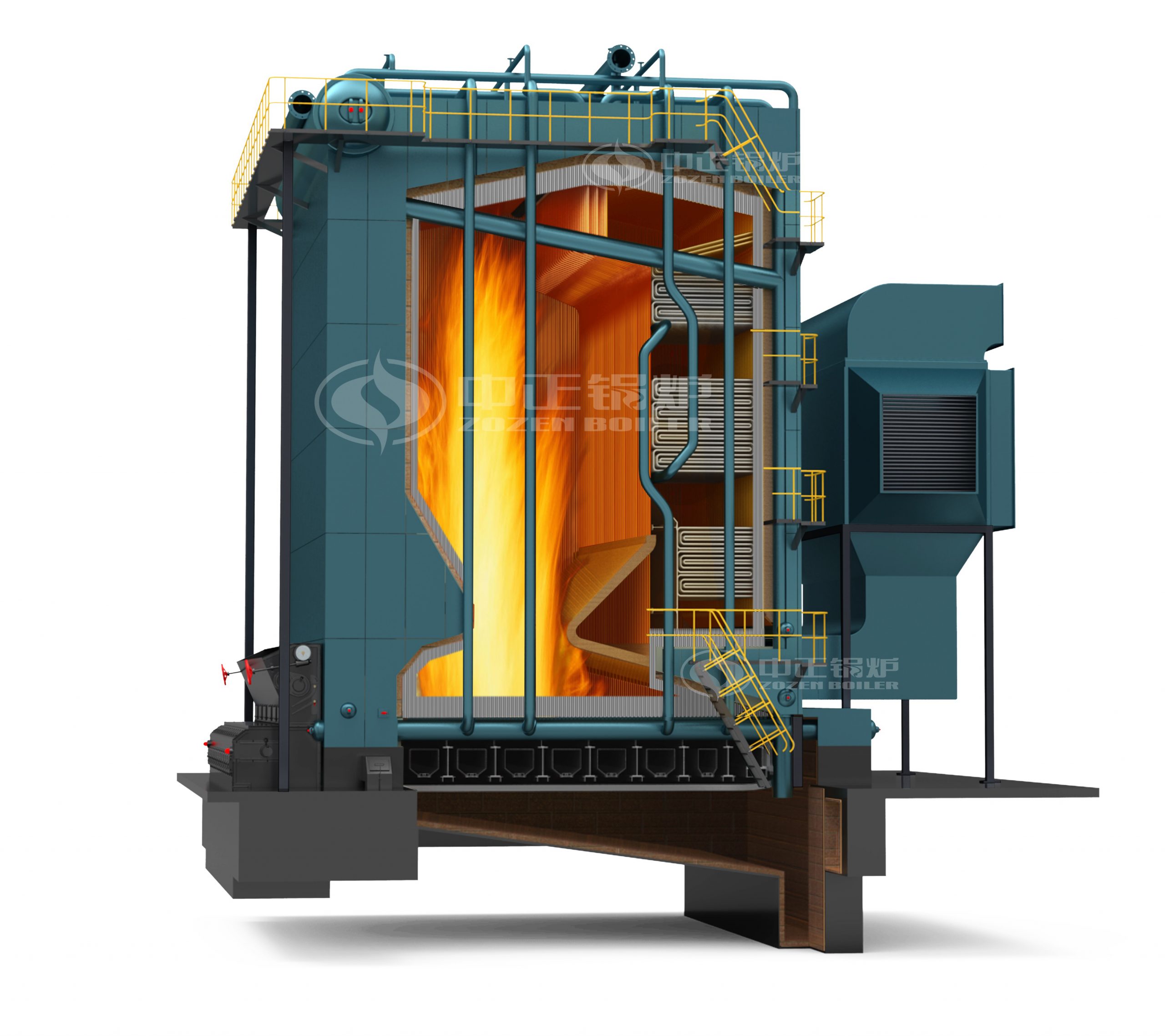

One prominent player in the industrial boiler domain is ZOZEN, a company with a rich background and a strong reputation. ZOZEN has amassed extensive experience in the field of industrial boilers, earning the trust and recognition of clients worldwide. Their commitment to excellence and continuous innovation has solidified their position as a leading provider of power plant steam boilers.

Part 3: High-Quality Power Plant Steam Boilers by ZOZEN

ZOZEN offers a range of high-quality power plant steam boilers, categorized by fuel type. For oil and gas fuels, the WNS series and SZS series are available. The WNS series power plant steam boiler is a three-pass wet-back boiler with a thermal capacity of 1-20 t/h and a working pressure of 0.7-2 MPa. Equipped with an advanced control system, it can operate unmanned, ensuring hassle-free operation. On the other hand, the SZS series power plant steam boiler features a double-drum, horizontal, D-type layout. It has a thermal capacity of 2-110 t/h and a working pressure of 1.25-5.3 MPa. The membrane water-cooled wall and large furnace design enhance heat transfer efficiency.

For biomass and coal fuels, ZOZEN offers the SZL, SHX, DZL, DHL, and DHX series. The SZL series power plant steam boiler is a horizontal, double-drum, chain grate, water tube boiler with a thermal capacity of 6-35 t/h and a working pressure of 1-2.5 MPa. Its furnace adopts a densely arranged water-cooled wall tube structure, providing a large radiation heating surface. The SHX power plant steam boiler is a circulating fluidized bed boiler with a thermal capacity of 10-75 t/h and a working pressure of 1.25-2.45 MPa. This boiler exhibits broad fuel adaptability and high combustion efficiency, making it ideal for low-calorific-value coals. The DZL series power plant steam boiler is a horizontal, three-pass, water-fire tube chain grate boiler with a thermal capacity of 2-10 t/h and a working pressure of 1-2.5 MPa. It adopts electrical control to achieve stepless speed regulation of grate. Limit parameter alarm and interlock protection. The DHL series power plant steam boiler is a corner tube boiler with a thermal capacity of 20-75 t/h and a working pressure of 1.25-5.4 MPa. It utilizes a horizontal beam chain grate and membrane water-cooled wall structure to ensure thorough fuel combustion. Finally, the DHX series power plant steam boiler is a circulating fluidized bed boiler with a thermal capacity of 35-75 t/h and a working pressure of 1.25-5.3 MPa. This boiler produces ash with excellent reactivity, facilitating comprehensive utilization and avoiding secondary ash pollution.

In addition to the aforementioned series, ZOZEN has developed a biomass boiler with independent intellectual property rights. The DZL series is a horizontal, ash-free biomass steam boiler with a thermal capacity of 15-40 t/h and a working pressure of 1.25-2.5 MPa. It features an ash blowing device at the rear of the furnace and ash blowing holes at the top, enabling ash cleaning without the need to halt operation.

ZOZEN DZL Series Ash-free Biomass Fired Power Plant Steam Boiler

Part 4: Emphasizing the Product Characteristics of ZOZEN

High Efficiency and Energy Saving: ZOZEN excels in combustion technology and incorporates innovative energy-saving devices into their boilers. This results in improved thermal efficiency and reduced energy consumption, contributing to sustainable power generation and environmental preservation.

Stability and Reliability: ZOZEN utilizes high-quality materials and advanced manufacturing processes to ensure the stability and reliability of their power plant steam boilers. Multiple safety protection devices are implemented to guarantee secure operations and prevent accidents.

Customized Design: ZOZEN offers tailored solutions to meet the specific requirements of their clients. Their flexibility in adapting to various power plant needs ensures that each boiler system is customized accordingly, optimizing efficiency and performance.

Conclusion

Power plant steam boiler is indispensable in the electricity generation process, and their efficiency and reliability are crucial for uninterrupted power supply. ZOZEN, with its expertise and reputation in the industrial boiler industry, provides a wide range of high-quality power plant steam boilers. Whether fueled by oil, gas, biomass, or coal, ZOZEN offers specialized series designed to meet diverse needs. With a focus on high efficiency, stability, and customized solutions, ZOZEN continues to be a trusted partner in the power generation sector.

Leave a Reply