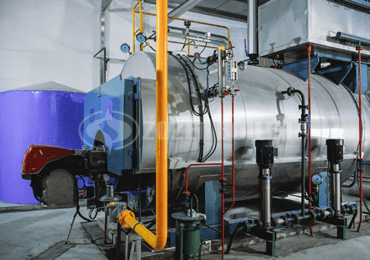

WNS Series Crude Oil Boiler

Product thermal capacity: 1 – 20 t/h

Working pressure: 0.7-2 MPa

Available fuel: Natural gas, coke oven gas, biogas, diesel, heavy oil, light oil, crude oil, etc.

Available industries: Heat supplying, chemical, food, textile, printing and dyeing, cigarettes and tobacco, fodder, pharmacy, building materials, brewery, rubber, hospital etc.

WNS Series Crude Oil Boiler Introduction

The WNS series crude oil boiler is a horizontal, internal combustion boiler designed with a fire tube type three-pass wet-back structure. It ensures the reliability and long-term stable operation of the boiler through the use of high-quality materials and advanced manufacturing processes. The boiler exhibits characteristics of high temperature resistance, corrosion resistance, and pressure resistance, making it suitable for various harsh operating conditions.

The WNS series crude oil boiler incorporates an advanced combustion control system and exhaust gas treatment equipment, effectively reducing the generation of emissions. It complies with strict environmental standards, thereby minimizing its impact on the environment. As a result, the WNS series crude oil boiler serves as a clean and sustainable energy solution.

WNS Series Crude Oil Boiler Advantages

Efficiency: The boiler adopts a fire tube type three-pass wet-back structure design, maximizing the utilization of thermal energy and achieving efficient combustion processes. It significantly saves energy and can generate more steam with less fuel consumption, thereby reducing energy costs.

Reliability: With high-quality materials and advanced manufacturing processes, the boiler ensures reliability and long-term stable operation. It possesses characteristics such as high temperature resistance, corrosion resistance, and pressure resistance, adapting to various harsh operating conditions, reducing downtime, and enhancing production efficiency.

Environmental-friendly: The boiler incorporates advanced combustion control systems and exhaust gas treatment equipment, effectively reducing emissions. It complies with stringent environmental standards, minimizing its impact on the environment, and providing customers with a clean and sustainable energy solution.

Ease of operation: Equipped with an advanced automatic control system, intelligent operating interface, and comprehensive safety measures, the boiler is easy to operate. Operators can effortlessly monitor and control the boiler’s operating status, ensuring safe and stable operation while reducing manpower requirements.

WNS Series Crude Oil Boiler Specification

| Model | Rated steam capacity (t/h) | Rated working pressure (MPa) | Rated steam temperature (℃) | Maximum transport weight (t) | Maximum transport dimension (m) |

| WNS1-0.7-Q(Y) | 1 | 0.7 | 170 | 4.5 | 3.25×1.80×2.00 |

| WNS1-1.0-Q(Y) | 1 | 1 | 184 | 4.5 | 3.25×1.80×2.00 |

| WNS1.5-1.0-Q(Y) | 1.5 | 1 | 184 | 7 | 3.65×2.05×2.45 |

| WNS1.5-1.25-Q(Y) | 1.5 | 1.25 | 194 | 7 | 3.65×2.05×2.45 |

| WNS2-1.0-Q(Y) | 2 | 1 | 184 | 9 | 4.60×2.20×2.60 |

| WNS2-1.25-Q(Y) | 2 | 1.25 | 194 | 9 | 4.60×2.20×2.60 |

| WNS3-1.0-Q(Y) | 3 | 1 | 184 | 11.5 | 5.35×2.40×2.80 |

| WNS3-1.25-Q(Y) | 3 | 1.25 | 194 | 11.5 | 5.35×2.40×2.80 |

| WNS4-1.25-Q(Y) | 4 | 1.25 | 194 | 15 | 5.00×2.60×2.95 |

| WNS4-1.6-Q(Y) | 4 | 1.6 | 204 | 15 | 5.00×2.60×2.95 |

| WNS5-1.25-Q(Y) | 5 | 1.25 | 194 | 18 | 5.55×2.658×3.20 |

| WNS5-1.6-Q(Y) | 5 | 1.6 | 204 | 18 | 5.55×2.658×3.20 |

| WNS6-1.25-Q(Y) | 6 | 1.25 | 194 | 19.5 | 5.93×2.80×3.20 |

| WNS6-1.6-Q(Y) | 6 | 1.6 | 204 | 19.5 | 5.93×2.80×3.20 |

| WNS8-1.25-Q(Y) | 8 | 1.25 | 194 | 25 | 7.00×2.80×3.25 |

| WNS8-1.6-Q(Y) | 8 | 1.6 | 204 | 25 | 7.00×2.80×3.25 |

| WNS10-1.25-Q(Y) | 10 | 1.25 | 194 | 27.5 | 7.65×2.80×3.25 |

| WNS10-1.6-Q(Y) | 10 | 1.6 | 204 | 27.5 | 7.65×2.80×3.25 |

| WNS15-1.25-Q(Y) | 15 | 1.25 | 194 | 40 | 7.95×3.50×3.75 |

| WNS15-1.6-Q(Y) | 15 | 1.6 | 204 | 40 | 7.95×3.50×3.75 |

| WNS20-1.25-Q(Y) | 20 | 1.25 | 194 | 52 | 8.55×3.90×4.15 |

| WNS20-1.6-Q(Y) | 20 | 1.6 | 204 | 52 | 8.55×3.90×4.15 |

Leave a Reply