ZOZEN always pursues the perfection of details to the utmost

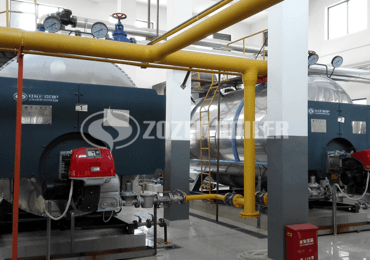

It is the unremitting pursuit of ZOZEN to do a good job in every detail and create value for users. ZOZEN’s ultimate pursuit of detail is expressed in every part of the boiler, every inspection and manufacturing process.

As early as the establishment of the company, ZOZEN has began to gradually introduce modern technology into the traditional production mode to realize the mechanization, informationization and intelligence of the boiler production line. The fully automated production line not only greatly increases production efficiency, but more importantly, the processing dimensions of individual boiler components are more precise, while minimizing product quality problems caused by human factors.

In the production process, the NC rate of the ZOZEN has reached over 80%. Compared with the flame cutting, the underwater plasma cutting machine used by the ZOZEN is no deformation and splashing, which further improves the assembly precision between the various components of the boiler, achieving accurate assembly of the entire boiler. In addition, regarding the treatment before welding, the three processes (rust removal, edge milling and chamfering) avoid the generation of a large number of pores in the welding lines to ensure the welding quality

Leave a Reply